Vibration control guidance

Vibration control guidance

How to mitigate risk from vibration?

Over exposure to vibration from using equipment, machinery or vehicles can represent significant health risks to employees.

The most commonly known of these risks is Hand Arm Vibration Syndrome (HAVS) - a general term for several conditions affecting blood vessels, nerves, muscles and joints. It is caused by excessive exposure to vibration of the hand and/or arms and characteristic symptoms are whitening of the fingers, numbness or lack of feeling, tingling, reduced strength of grip and reduction in manual dexterity.

However, regular long term exposure to Whole Body Vibration (WBV) also represents a risk. WBV describes vibration transmitted through the seat or feet whilst using vehicles and is associated with back pain alongside other factors such as poor posture and heavy lifting.

Our recommended actions:

Employers must:

- Assess the vibration risk to your employees

- Decide if they are likely to be exposed above the daily exposure action value (EAV) and, if they are, introduce a programme of controls to eliminate or reduce their daily exposure so far as is reasonably practicable

- Decide if they are likely to be exposed above the daily exposure limit value (ELV) and, if they are, take immediate action to reduce their exposure below the limit value

- Keep a record of your risk assessment and control actions

- Review and update your risk assessment regularly

Control actions could include:

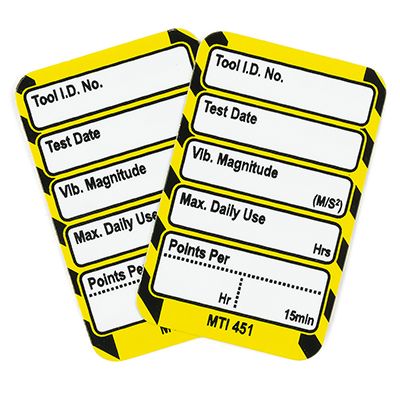

- Making vibration level measurement information available on all applicable tools, plant, vehicles and machinery and record these in a register

- Conducting appropriate exposure monitoring and health surveillance